Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

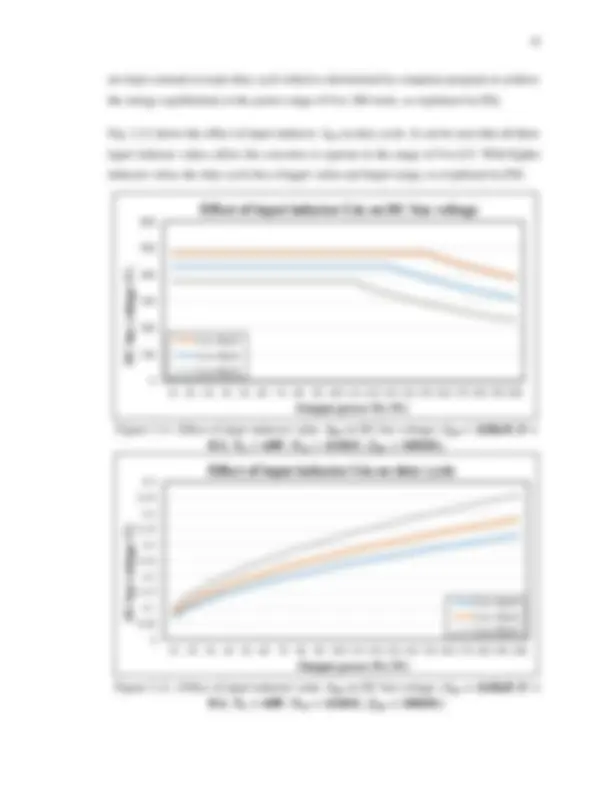

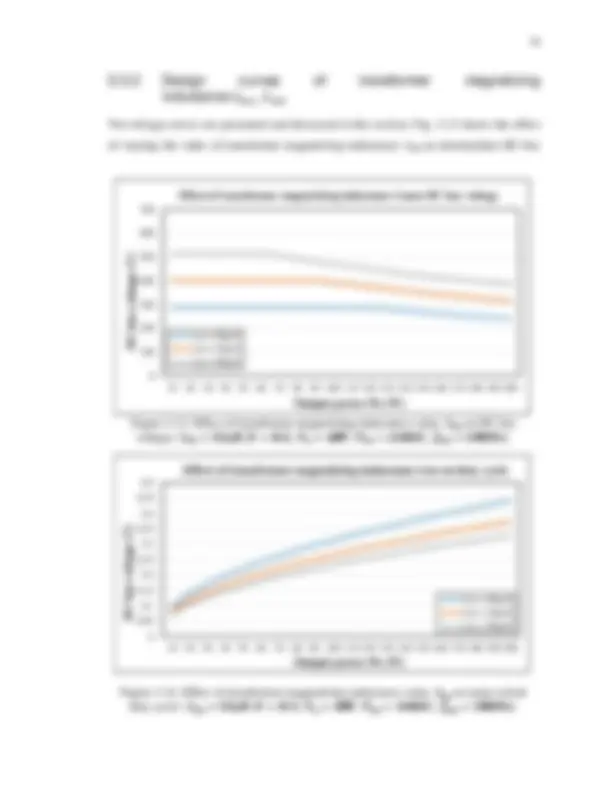

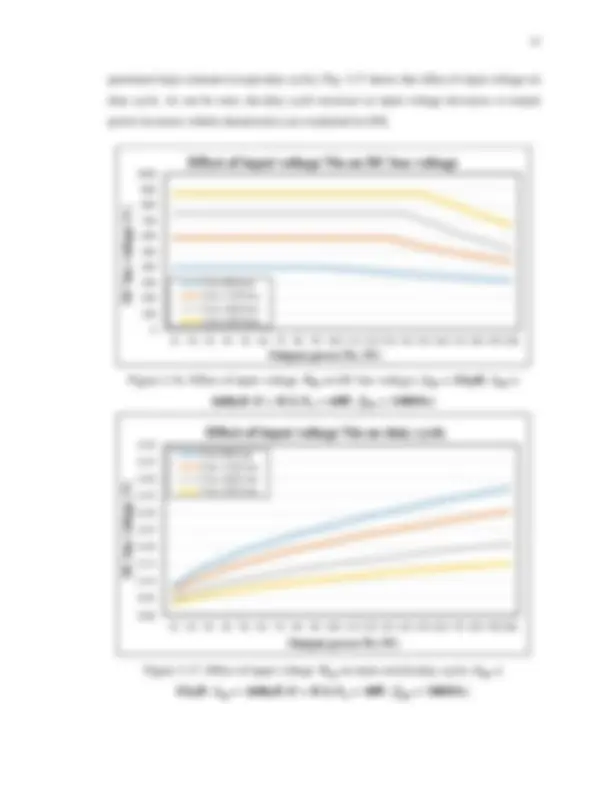

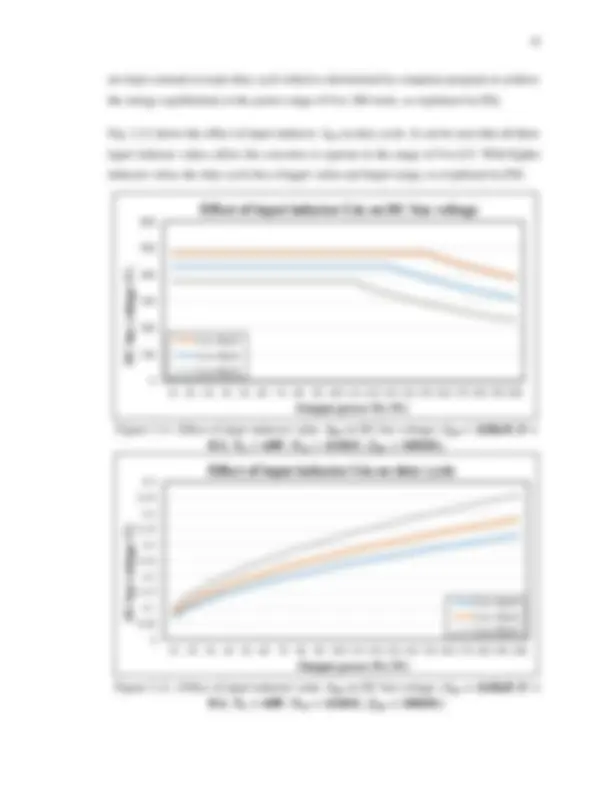

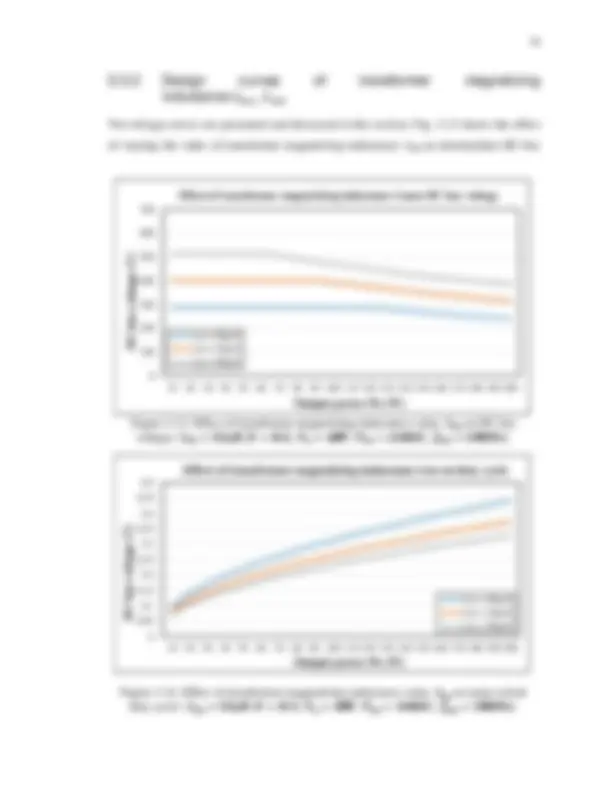

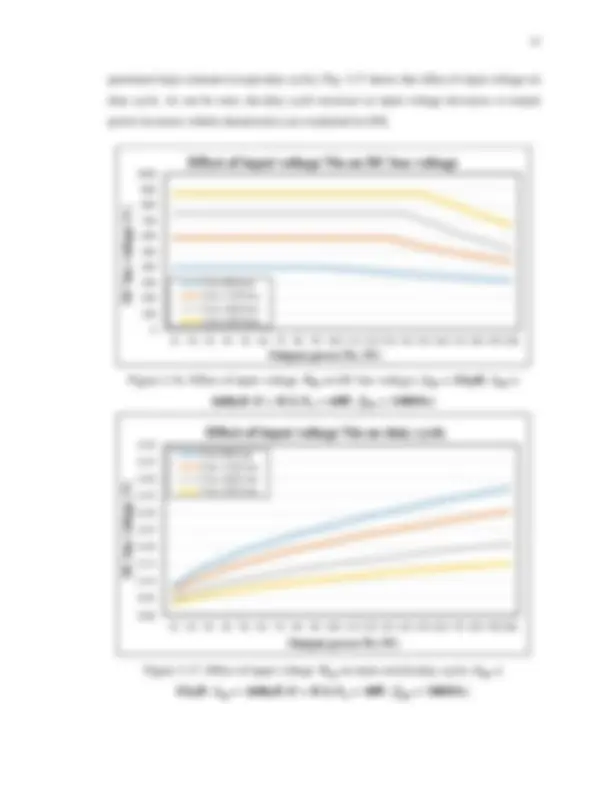

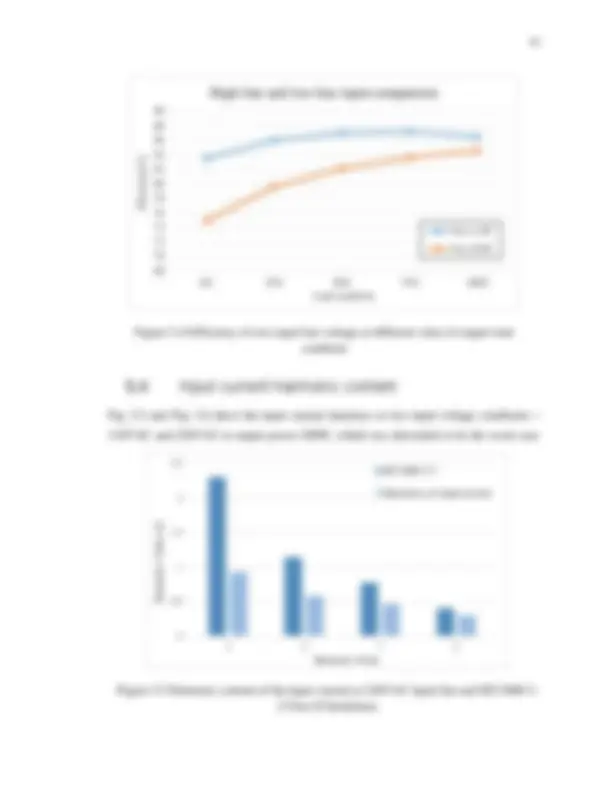

A detailed circuit analysis and design curves for a single-stage ac-dc converter. The analysis covers the effect of various parameters such as input inductor, transformer magnetizing inductance, and transformer turns ratio on the dc bus voltage and duty cycle of the converter. Design curves are provided to illustrate the relationships between these parameters and the converter's performance. The document also discusses the advantages of the proposed stacked topology, which helps to reduce the voltage stress on the converter components compared to conventional single-stage converters. Overall, this document provides valuable insights into the design and optimization of single-stage ac-dc converters for various power applications.

Typology: Study notes

1 / 44

This page cannot be seen from the preview

Don't miss anything!

2 AC-DC Single-Stage Stacked Flyback Converter

The proposed AC-DC single-stage converter is introduced in this chapter. The converter is

based on the concept of stacking single-stage converter modules on top of each other. In

this chapter, the general operation and the modes operation of proposed converter are

explained, the features of the proposed converter are stated and the extension of the stacked

converter concept to other single-stage converter modules is discussed.

The proposed converter is shown in Fig. 2.1. It is made up of two flyback converters that

are stacked on top of each other at the primary and connected in parallel at the output, an

active clamp auxiliary circuit that is used to help the main power switches turn on with

zero-voltage switching (ZVS) and a front-end AC-DC boost section that consists of a diode

Figure 2. 1 : Single-stage single-phase AC-DC stacked flyback converter.

bridge, an input inductor Lin and two auxiliary windings that are each taken from one of

the flyback transformers and that are each connected in series with a blocking diode.

Inductances 𝐿𝑙𝑘 1 and 𝐿𝑙𝑘 2 may be a combination of the transformer leakage inductances

and some external inductances or just the leakage inductances. 𝐿𝑙𝑘 1 and 𝐿𝑙𝑘 2 help in the

ZVS operation of the converter by storing energy that can be later used to discharge the

switch output capacitances before turn-on.

The auxiliary windings act as ‘magnetic switches’ that cancel the DC bus capacitor voltage

so that the voltage that appears at the right-hand side of input inductor 𝐿𝑖𝑛 is zero. When

the upper switch S 1 is on, the primary voltage of the main transformer 𝑇 1 is positive,

auxiliary winding (𝑁𝑎𝑢𝑥 1 /𝑁 1 =2) that cancels out the DC bus voltage so that the currents in

input inductors Lin rise. When the lower switch S 2 is on, the primary voltage of the main

transformer is negative, auxiliary winding (𝑁𝑎𝑢𝑥 2 /𝑁 1 =2) cancels out the DC bus voltage so

that the currents in input inductors Lin rise. When there is no voltage across the main

transformer primary winding, the total voltage across the DC bus capacitors appears at the

output of the diode bridges and the input currents fall since this voltage is greater than the

input voltage. If the input current is discontinuous, it has a sinusoidal envelope and is in

phase with the input voltage.

Typical converter waveforms are shown in Fig. 2.2 and equivalent circuit diagrams that

show the converter’s modes of operation are shown in Fig. 2.3 with the diode bridge output

replaced by a rectified sinusoidal voltage source. The converter has the following modes

of operation during an entire switching cycle.

Mode 1 (t 0 < t < t 1 ): (Fig. 2.3(a))

In this mode, switch S 1 is ON and the energy is stored in the transformer 𝑇 1. At the same

time, since 𝑆 2 is OFF, stored energy in the magnetizing inductance of transformer 𝑇 2 is

transferred to the load. Since the auxiliary winding generates a voltage that is equal to the

total DC bus voltage with opposite polarity, which cancels the total DC bus capacitor

Mode 3 (t 2 < t < t 3 ): (Fig. 2.3(c))

In Mode 3, the auxiliary switch S 3 is turned ON to start this mode. The stored energy in

capacitor 𝐶𝑐 flows through the leakage inductor 𝐿𝑙𝑘 2 , the primary winding of the

transformer 𝑇 2 , the primary winding of transformer 𝑇 1 , the inductor 𝐿𝑙𝑘 1 , and auxiliary

switch 𝑆 3. Since the output diode is ON during this mode, there is no energy stored in

transformer 𝑇 1.

Mode 4 (t 3 < t < t 4 ): (Fig. 2.3(d))

In this mode, switch 𝑆 3 is OFF. Current in the leakage inductance of 𝑇 2 , 𝐿𝑙𝑘 2 , flows through

the output capacitor of 𝑆 2 and bulk capacitor C 2. It discharges the output capacitor of 𝑆 2 so

that 𝑆 2 can be turned on with ZVS. This also happens for 𝑆 1 and the output capacitor of 𝑆 1

discharges in Mode 8. Since 𝑆 1 is not turned ON, its output capacitor is eventually fully

recharged.

Mode 5(t 4 < t < t 5 ): (Fig. 2.3(e))

In this mode, switch 𝑆 2 is ON with ZVS. The primary current flows through the

magnetizing inductance of 𝑇 2 and increases while the stored energy in the magnetizing

inductance of 𝑇 1 is transferred to the load through the secondary diode.

Mode 6 (t 5 < t < t 6 ): (Fig. 2.3(f))

In this mode, switch S 2 is OFF. The only path for the stored energy in leakage inductance

𝐿𝑙𝑘 2 is to flow through capacitor Cc and the body diode of the active clamp switch 𝑆 3

through the lower bus capacitor C 1 and the output capacitor of S 2.

Mode 7 (t 6 < t < t 7 ): (Fig. 2.3(g))

The auxiliary switch S 3 is turned ON at the start the mode. The stored energy in capacitor

Cc flows through the leakage inductor 𝐿𝑙𝑘 2 , the primary winding of the transformer 𝑇 2 , the

primary winding of transformer 𝑇 1 , the inductor 𝐿𝑙𝑘 1 , and auxiliary switch 𝑆 3. Since the

output diode is ON during this mode, there is no energy stored in transformer 𝑇 2.

Mode 8 (t 7 < t < t 8 ): (Fig. 2.3(h))

In this mode, auxiliary switch S 3 is OFF. Current in inductor 𝐿𝑙𝑘 1 flows through the output

capacitor of S 1 and bulk capacitor C 1. It discharges the output capacitor of S 1 so that S 1 can

Vrec

S

C

C

Cc

S

S

Vrec

S

C

C

Cc

S

S

Lin Lin

Llk

Llk

Llk

Llk

(a) (b)

Vrec

S

C

C

Cc

S

S

Vrec

S

C

C

Cc

S

S

Lin

Llk

Llk

Llk

Llk

Lin

(c) (d) Figure 2. 3 : Modes of operations

The proposed converter has the following features:

stacked topology. The converter components on the primary side (i.e. switches) are exposed to just half the DC bus voltage.

stacked single-stage converters, there is greater flexibility in the design of the converter. Most notably, the input current conduction angle does not have to be limited so that input current distortion is reduced and input power factor is increased.

switch instead of having to use two auxiliary switches – one for each switch.

reduced as the converter switches are exposed to only half the DC bus voltage. Most converters with auxiliary circuits for ZVS operation are either ineffective when the converter is operating with light loads or create more losses than they save under these conditions. The proposed converter has superior light-load efficiency.

to around 50% maximum because the converter has two switches instead of one. In conventional single-stage flyback converters, operating with a duty-cycle above 50% means that peak voltage stress of the single switch must be increased considerably or the converter must operate with small duty cycles at high-line voltages. For the proposed converter, the peak voltage stress in the switches is much less because switch duty cycles > 50% are avoided; this reduction is on top of the voltage stress reduction due to the stacked topology. In other words, two lower power rated, cheaper and more widely available devices can be used instead of a very expensive single device.

The proposed converter is just one way of implementing the stacked converter concept. In

general, it can be implemented with any single single-stage converter module that has

auxiliary windings from the main transformer. The basic idea is to stack one module on

top of the other as shown in Fig. 2.4, then connect the auxiliary windings appropriately at

the input and interleave the output windings as in Fig. 1.7(a). How this can be accomplished

will be explained as follows in this section of the thesis. Much of the following discussion

is taken from [10].

Although many single-stage AC-DC flyback converters, which are referred to as input

current shapers (ICSs) in [ 10 ], have been proposed, these converters share a number of

common properties. A number of ICSs can be classified as being two-terminal ICSs and

three-terminal ICSs, as shown in Fig. 2.5 and Fig. 2.6. Two-terminal ICSs operate based

on the principle of the ‘magnetic switch’ must like the module converters in the proposed

converter. The basic structure of a two-terminal ICS is shown in Fig. 2.7(a), where it can

be seen that the ICS has a discharge branch and a charge branch and that the two branches

are in parallel. The input inductor current is made to rise by ‘charging’ the inductor through

the charge branch and is made to fall by allowing current to flow into the ‘discharge’

branch. In the proposed converter, which uses two-terminal ICS modules, current flowing

through the charge branch corresponds to Mode 1 of operation and current flowing through

the discharge branch corresponds to Mode 5 of operation.

Three-terminal ICSs also have discharge and charge branches, but the charge branch is not

connected in parallel to the discharge branch. This branch is, instead connected to the input

switch as shown in Fig. 2.7(b). The proposed converter can be implemented with two-

terminal ICSs, but not with three-terminal ICSs because only modules with magnetic

switches can be used. It is, however, possible to convert a three-terminal ICS into a two-

terminal ICS, as explained in [ 10 ].

Vo

AC

Auxiliary winding 1

Auxiliary winding 2

Lin

Figure 2. 4 : Modular diagram of proposed stacked single-stage converter concept.

Cb (^) Vo

Lin

N1 N

Q

Oc

Osw AC 3-terminal ICS cell

(a)

Cb Vo

Lin

N1 N

Q

N Osw

Oc

3-terminal ICS cell

AC

(b)

Cb Vo

Lin

N1 N

Q

N Osw

N Oc

AC 3-terminal ICS cell

(c)

Cb (^) Vo

Lin

N1 N

Q

Cb Osw

Oc

AC 3-terminal ICS cell

(d) Figure 2. 6 : Example single-stage converters with three-terminal input current shaper (ICS) cells [10].

The general rule is to take a three-terminal ICS cell and add an extra winding as shown in

Fig. 2.8(a). The polarity of the added winding should be such that the equivalent circuit

before and after the translation is the same when the switch is on, as shown in Fig. 2.8(b).

The number of turns of the added winding should equal that of primary winding of the

transformer in the DC-DC converter section if the original three-terminal ICS charge

branch had a direct connection to the main converter switch. If the connection is through

an auxiliary winding that produces a counter voltage to change the energy equilibrium at

the DC bus to a more favorable one like the converter shown in Fig. 2.9 [ 42 ], then the

number of turns of the added winding should be such that the counter voltage is reproduced

Cb Vo

Lin

N1 N

Q

Osw AC 2-terminal ICS cell

Discharge Branch

Charge Branch

(a)

Cb Vo

Lin

N1 N

Q

Osw AC 3-terminal ICS cell

Discharge Branch

Charge Branch

(b)

Figure 2. 7 : Single-stage PFC with generic ICS cell (a) two-terminal (b) three-terminal [10].

The proposed AC-DC single-stage converter was introduced in this chapter. In this chapter,

the general operation and the modes of proposed converter were explained and its features

were stated. Since the converter’s topology was based on the stacking of single-stage

converter modules on top of each other, the extension of the stacked converter concepts to

other single-stage converter modules was discussed. In order for a single-stage converter

to be implemented as a module in a stacked converter, it must have a magnetic switch.

Such a switch is implemented using an auxiliary winding from the main transformer. It was

shown in this chapter that numerous, previously proposed single-stage converters, whether

they be two-terminal input current shapers or three-terminal input current shapers, can be

stacked as long as they have magnetic switches or have equivalent topologies with

magnetic switches.

AC

Cb (^) Vo

Lin

N1 N

S

Cf N

Figure 2. 9 : AC-DC single-stage converter with auxiliary winding that produces counter voltage proposed in [ 42 ].

3 Circuit Analysis

In the previous chapter, the general operation and the key modes of operation of the

proposed converter were explained. The steady-state characteristics of key converter

parameters are determined by a mathematical analysis of the converter’s modes of

operation in this chapter. In this chapter, mathematical equations that define each mode of

the proposed converter are derived and these equations form the basis of a computer

program that will allow graphs of characteristic curves to be plotted. These graphs will then

be used in the next chapter to develop a procedure for the design of the proposed converter.

For the steady-state analysis of the proposed converter’s modes of operation, the following

assumptions have been made:

This allows each converter modules to emulate a single-stage converter with no counter voltage applied to its input inductor. This counter voltage reduces the amount of energy stored in the input inductor and affects the energy equilibrium at the DC bus.

bus capacitor 𝐶 1 and 𝐶 2 are the same, the switches, semiconductors, transformer ratings are the same).

The objective of the steady-state analysis is to obtain the current that goes in and goes out

of the intermediate DC bus capacitor. As mentioned in previous chapters, single-stage AC-

DC converters do not have control of the DC bus voltage because they only have one

controller to regulate the output voltage. Under steady-state conditions, the average current

total DC bus voltage, but with opposite polarity. The input voltage across the input inductor

is thus the rectified supply voltage so that input current in Lin rises according to

where |𝑣𝑖𝑛,𝑘| is the rectified AC input voltage during switching cycle interval k. The input

voltage can be considered to be a constant value in a single switching cycle as the switching

frequency is much higher compared with the AC input line frequency. The current in the

input inductor 𝐿𝑖𝑛 at the end of Mode 1 is

Duty cycle D is defined as the time when main switch 𝑆 1 or 𝑆 2 is ON during the entire

switching cycle (two switches are ON for exactly the same length of time but in alternative

half cycles). The two switches are each operated in during an alternative half switching

cycle 𝑇𝑠𝑤/ 2 or 2 𝑓𝑠𝑤 where 𝑓𝑠𝑤 is the switching frequency of the main switch.

Mode 2 (t 0 < t < t 1 ): (Fig. 3.2)

The equivalent circuit of Mode 2 is shown in Fig. 3.2. Because there is no switch closed

during this mode, the current in the circuit is circulating and energy in the leakage

C

Cc (^) Vo

Llk

Figure 3. 2 : Equivalent circuit of Mode 2.

inductance flows though the active clamp capacitor. Following Kirchhoff’s Voltage Law

(KVL), the following equation can be established:

where the two bus capacitors equally divide the DC bus voltage. 𝐿𝑙𝑘 1 is the leakage

inductance of the upper converter transformer while 𝐿𝑚 1 is the magnetizing inductance of

upper converter transformer. 𝑉𝑐𝑙𝑎𝑚𝑝 is the voltage across the clamp capacitor. During this

mode, the energy in main transformer 𝑇 1 is transferred to the output load until the current

in the transformer goes zero. The output voltage can be expressed as follows:

where N is the transformer turns ratio between the primary and secondary (𝑁 1 /𝑁 2 ).

Mode 3 (t 0 < t < t 1 ): (Fig. 3.3)

The equivalent circuit of Mode 3 is shown in Fig. 3.3. Auxiliary switch S 3 is turned ON

with ZVS. The energy in transformer T 1 is transferred to the output load while the energy

in clamp capacitor is transferred to leakage inductor 𝐿𝑙𝑘 2 , according to

Figure 3. 3 : Equivalent circuit of Mode 3.

bus voltage. As the converter specification is exactly the same, the current in the input

inductor in Mode 5 in the second part of the switching cycle is same in Mode 1 according

to

The current is bounded by a sinusoidal envelope related to the input rectifier voltage, as

shown in Fig. 3.6, and it rises and falls twice in one switching cycle 𝑓𝑠𝑤. The ON time for

each switch is

so that the total input current in interval k is

Vrec

Lin

Llk

Figure 3. 5 : Equivalent circuit of Mode 5

The input inductor current flows into the DC bus capacitor as it is the only path that is

available to it; therefore, the average current of the input current is the same current injected

into the DC bus. By accumulating all the switching intervals together, the average current

flowing into the DC bus during AC line cycle is

𝑛

𝑘= 0

where 𝑓𝑎𝑐 the frequency of AC is input line and n is the number of interval in one AC line

cycle

𝑣𝑟𝑒𝑐 is the rectified voltage output from the rectified diode bridge that can be determined

as follows

𝑣𝑟𝑒𝑐 = 𝑉𝑟𝑚𝑠 ∙ |sin( 2 𝜋𝑘/𝑛)| (3.12)

Equ. (3.10) will eventually be compared to the average current flowing out of the DC bus

to determine whether an energy equilibrium has been established and the converter is

operating in steady-state.

Figure 3. 6 : DCM operation on input inductor.